Mastering In-Mold Decorations: Approaches, Fads, and Finest Practices for Optimal Outcomes

In the realm of manufacturing, the art of in-mold decors stands as an essential aspect of item style and manufacturing. As sectors continuously seek cutting-edge methods to enhance aesthetic appeal and performance, mastering the details of in-mold decors has arised as an important skill set. From choosing the ideal materials to including advanced layout fads, the trip in the direction of accomplishing ideal outcomes in this domain is multifaceted. By diving right into the methods, fads, and best methods that underpin effective in-mold decor procedures, companies can open a world of opportunities that not just boost the aesthetic allure of their products however likewise simplify manufacturing efficiency and reinforce consumer interaction.

Product Choice

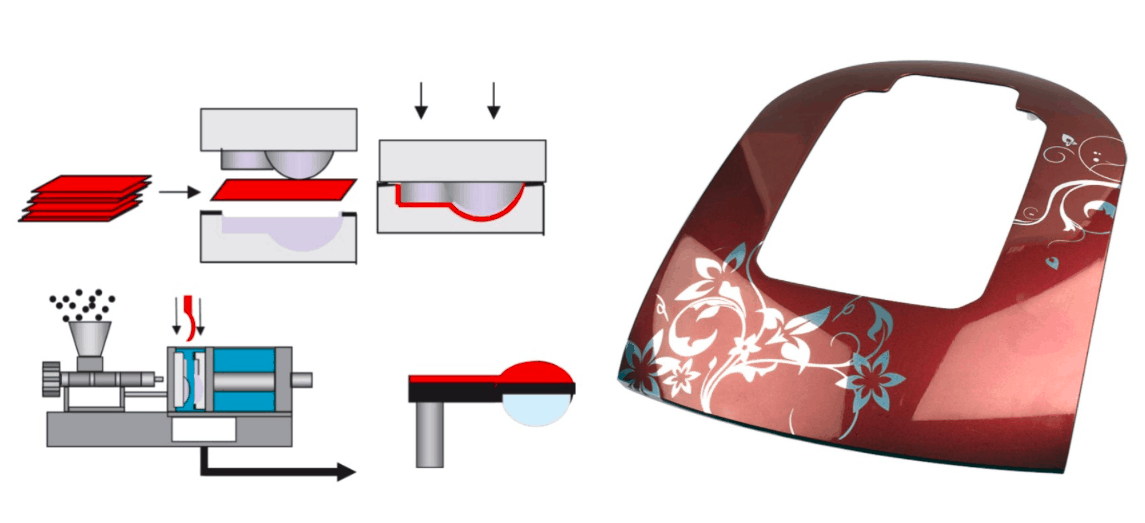

Product option is a vital element of mastering in-mold decorations, as it straight affects the top quality and resilience of the end product. When picking products for in-mold designs, it is important to take into consideration variables such as compatibility with the molding procedure, the preferred aesthetic end result, and the ecological problems the item will face. Polycarbonate products like abs, polypropylene, and polycarbonate are frequently used for in-mold decorations as a result of their flexibility and capacity to attain elaborate designs. These products offer superb moldability, making it possible for makers to create intricate shapes and patterns with accuracy.

In addition, products with high warm resistance are favored for in-mold decorations, especially for items that will certainly be exposed to raised temperatures throughout their lifecycle. By very carefully selecting the appropriate product for in-mold designs, manufacturers can enhance the general high quality and sturdiness of their items, fulfilling the expectations of both end-users and clients - In-Mold Decorations.

Layout Advancement

A necessary aspect in advancing the field of in-mold decorations is the continuous exploration and implementation of design technology techniques. Design technology plays a critical role in improving the visual charm, functionality, and overall high quality of items made using in-mold decor procedures. By integrating cutting-edge layout elements, producers can distinguish their products out there, bring in consumers, and remain ahead of competitors.

Among the essential facets of design advancement in in-mold designs is the integration of detailed patterns, appearances, and graphics that were formerly testing to achieve with standard design methods. Advanced modern technologies such as 3D printing and digital style devices allow designers to create complex and in-depth styles that can be perfectly moved onto shaped parts. In addition, making use of lively shades, metal finishes, and unique effects like gloss or matte appearances can further boost the visual appeal of in-mold decorated products.

In addition, style advancement expands past aesthetics to include useful improvements such as ergonomic shapes, integrated features, and adjustable components that accommodate certain individual requirements. By accepting layout development, producers can unlock new opportunities for customization, product, and creativity differentiation in the competitive landscape of in-mold decors.

Production Effectiveness

Efficient production processes are vital for converting the ingenious layouts created in the area of in-mold designs right into high-quality ended up items that meet market needs and customer expectations. In the realm of in-mold decors, manufacturing effectiveness includes various vital elements that contribute to the overall success of the manufacturing procedure.

Automation not just increases the production process but additionally boosts accuracy and repeatability, leading to a more top quality and uniform end product. Generally, an all natural strategy to manufacturing efficiency is extremely important in maximizing the potential of in-mold decoration techniques and achieving optimal results in the competitive market landscape.

Quality Control Steps

What are the essential techniques for making sure strict quality assurance measures in the world of in-mold decors? Quality control steps are critical in in-mold decoration procedures to make certain the manufacturing of high-quality and flawless finished products. One vital technique is the application of extensive assessment procedures at every phase of the manufacturing procedure. This involves performing complete visual assessments, dimensional checks, and color uniformity evaluations to identify any kind of inconsistencies or flaws early.

Using innovative innovations such as computerized inspection systems can likewise enhance the quality assurance process by giving trusted and accurate data for evaluation. These systems can detect flaws that might be missed out on by manual assessments, therefore boosting general visit the site product top quality and consistency.

Regular training and advancement programs for staff members involved in the in-mold decoration procedure can additionally add to preserving high-grade standards. By educating personnel on ideal practices, high quality expectations, and the value of focus to information, companies can foster a culture of top quality consciousness throughout the organization.

Customer Appeal

To boost the bankability of in-mold decoration items, recognizing and catering to consumer choices play a vital function in establishing their charm and success. Consumer allure in in-mold decorations is influenced by numerous variables, consisting of layout aesthetics, color choices, sturdiness, and general performance. Consumers are significantly looking for customized and distinct products that reflect their uniqueness and style. As a result, using modification choices such as individualized styles, color variants, and textural components can dramatically boost the charm of in-mold design products.

Verdict

In-mold decorations provide a reliable and functional way to improve item looks. By very carefully picking products, embracing innovative styles, enhancing production processes, carrying out quality assurance actions, and focusing on customer allure, suppliers can attain optimum results. It is critical for companies to constantly adjust and improve their techniques to stay affordable on the market. In-Mold Decorations. Mastering in-mold decors requires an all natural strategy that considers all elements of the production procedure to make certain success.

In the realm of production, the art of in-mold designs stands as a crucial element of item layout and production. Layout advancement plays look what i found a critical function in enhancing the visual allure, capability, and general quality of items produced making Get the facts use of in-mold design procedures.One of the crucial facets of style innovation in in-mold decors is the integration of detailed patterns, textures, and graphics that were formerly challenging to accomplish with standard design methods.Efficient production procedures are necessary for translating the ingenious designs created in the field of in-mold designs right into top notch finished products that fulfill market demands and customer assumptions. Providing modification options such as tailored designs, color variants, and textural elements can significantly improve the allure of in-mold decoration products.